By Ana Verayo, | January 12, 2016

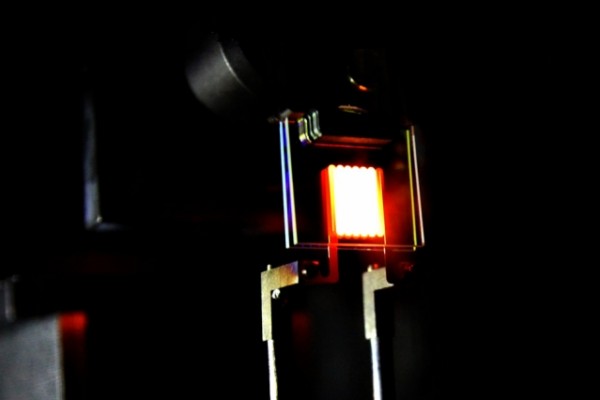

A proof-of-concept device built by MIT researchers demonstrates the principle of a two-stage process to make incandescent bulbs more efficient.

Researchers from the U.S. claim to have developed a new method that can significantly improve how the old, incandescent light bulb works, making it more efficient. These traditional bulbs have already been phased out in many countries around the world since they waste massive amounts of energy into heat.

Like Us on Facebook

Now, scientists from MIT (Massachusetts Institute of Technology) have discovered a new method to recycle this escaping energy or heat while recycling it back on the filament, as it is emitted again as visible light.

Ever since the 1880s, when Thomas Edison helped mass produce the incandescent light bulb in the U.S., the technology behind this traditional bulb pretty much remained the same ever since then.

The light bulb works by using electricity to heat this thin wire filament made of tungsten to high temperatures of about 2,700 degrees Celsius. This filament will then glow and can generate a broad spectrum producing warm, white light.

However, the incandescent light bulb remains to be really inefficient when it comes to energy usage as it can only convert two to three percent of the energy it uses to light, where the rest is emitted as heat. Ever since then, these bulbs have been banned by the European Union and Canada, where manufacture and importation has been discontinued in the U.S.

Replacing them are more expensive yet more efficient compact fluorescent and LED bulbs, with an efficiency of more than 13 percent.

In this new study, researchers at MIT believe that their new technique can transform the incandescent bulb with a new light by using its weak feature into an effective tool.

With the help of nanotechnology, scientists have made a structure surrounding the filament of the bulb, capturing the leaking infrared radiation so that it can reflect back to the filament, re-absorbing again and emitted back as visible light.

This special structure will be made from thin layers of a light controlling crystal where they are specially designed so that layers are stacked together, allowing visible wavelengths to pass through, as infrared will be reflected back to the filament, similar to how a mirror works.

According to lead author of the paper, Ognjen Illic, it is not about the material that surrounds the structure but it is how the material is arranged, that it can create an optical filtering property to recycle infrared light and allow visible light through.

MIT researchers theorize that these crystal structures can boost the efficiency of these traditional light bulbs by 40 percent, making them three times more effective than the best LED or fluorescent bulbs on the market today.

This new study is published in the journal Nature Nanotechnology.

-

Use of Coronavirus Pandemic Drones Raises Privacy Concerns: Drones Spread Fear, Local Officials Say

-

Coronavirus Hampers The Delivery Of Lockheed Martin F-35 Stealth Fighters For 2020

-

Instagram Speeds Up Plans to Add Account Memorialization Feature Due to COVID-19 Deaths

-

NASA: Perseverance Plans to Bring 'Mars Rock' to Earth in 2031

-

600 Dead And 3,000 In The Hospital as Iranians Believed Drinking High-Concentrations of Alcohol Can Cure The Coronavirus

-

600 Dead And 3,000 In The Hospital as Iranians Believed Drinking High-Concentrations of Alcohol Can Cure The Coronavirus

-

COVID-19: Doctors, Nurses Use Virtual Reality to Learn New Skills in Treating Coronavirus Patients