By Vishal Goel, | February 08, 2017

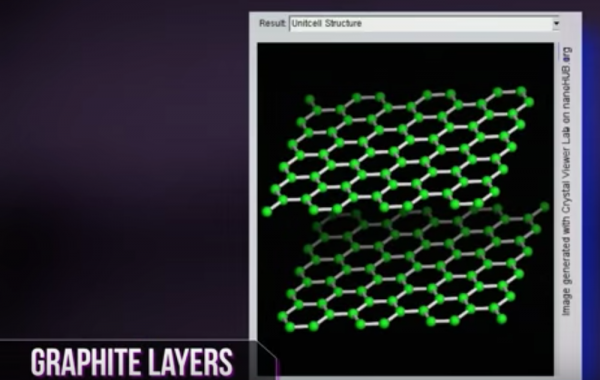

Graphene is only 0.3 nanometers thick and consists of a single layer of carbon atoms assembled in a kind of honeycomb pattern. (YouTube)

Scientists in Australia recently created graphene using soybean oil. Graphene, a carbon material that is one-atom think, is said to be 200 times stronger than steel. The scientists used a technology called "GraphAir" which involves heating soybean oil to decompose it into carbon building blocks which are cooled into a graphene film, thinner than a human hair. The leftover cooking oil can be re-used further in the process, which could drastically reduce its price, said the lead.

Like Us on Facebook

Applications of Graphene

Graphene has a thin composition and high conductivity which makes it perfect to be used in applications ranging from miniaturised electronics to biomedical devices. These properties also enable thinner wire connections, providing extensive benefits for solar panels, batteries, computers, sensors and other devices. The potential applications of graphene also include water filtration and purification, renewable energy, personalised healthcare and medicine. Graphene has excellent electronic, mechanical, thermal and optical properties as well.

Until now, high cost of graphene production has been a major roadblock in its commercialisation because it has been grown in a highly-controlled environment with explosive compressed gases which requires long hours of operation at high temperatures and extensive vacuum processing. Therefore, the CSIRO scientists developed the novel "GraphAir" technology which eliminates the need for such a highly-controlled environment. The technology grows graphene in ambient air with a natural precursor, making its production faster and simpler.

As told by CSIRO scientist Dr Zhao Jun Han who is also a co-author of the paper, this ambient-air process for graphene production is fast, safe and simple, potentially scalable, and integration-friendly. "Our unique technology is expected to reduce the cost of graphene production and improve the uptake in new applications."

The team also transformed other types of renewable including the waste oil into graphene films. "We can now recycle waste oils that would have otherwise been discarded and transform them into something useful," said Dr Seo, another co-author in the study published in Nature Communications.

CSIRO is looking to find new uses for graphene in the industry. Researchers from University of Technology Sydney,The University of Sydney and The Queensland University of Technology also contributed to this work.

-

Use of Coronavirus Pandemic Drones Raises Privacy Concerns: Drones Spread Fear, Local Officials Say

-

Coronavirus Hampers The Delivery Of Lockheed Martin F-35 Stealth Fighters For 2020

-

Instagram Speeds Up Plans to Add Account Memorialization Feature Due to COVID-19 Deaths

-

NASA: Perseverance Plans to Bring 'Mars Rock' to Earth in 2031

-

600 Dead And 3,000 In The Hospital as Iranians Believed Drinking High-Concentrations of Alcohol Can Cure The Coronavirus

-

600 Dead And 3,000 In The Hospital as Iranians Believed Drinking High-Concentrations of Alcohol Can Cure The Coronavirus

-

COVID-19: Doctors, Nurses Use Virtual Reality to Learn New Skills in Treating Coronavirus Patients